The Electric & Diesel Telescopic Lift Cherry Picker Tracked Spider Crane represents a significant advancement in lifting technology. This innovative machine combines the flexibility of electric power with the reliability of diesel fuel, making it suitable for a wide range of applications. As a tracked spider crane, it offers enhanced mobility and stability on various terrains, ensuring efficient and safe operations in both indoor and outdoor environments.

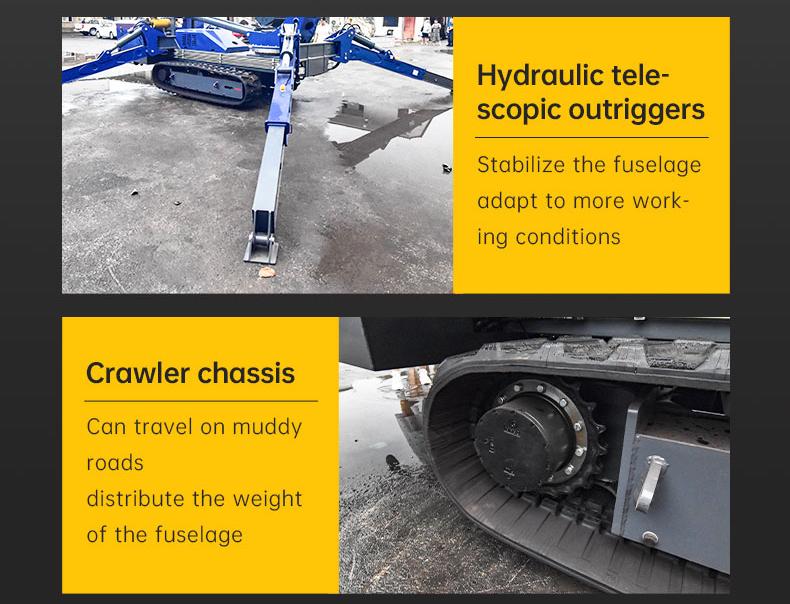

The telescopic outrigger system of this tracked spider crane provides exceptional stability and adaptability. The outriggers can extend to create a larger stabilizing base, allowing the crane to handle heavy loads securely. The telescopic design also makes it easy to transport and set up the crane, as the outriggers can be retracted to a compact size. This system ensures that the crane remains stable on uneven or narrow surfaces, reducing the risk of accidents during operation.

This electric & diesel spider crane is equipped with advanced tracked mechanisms. The tracks provide superior traction and reduce ground pressure, enabling the crane to move smoothly over various terrains, including grassy areas, gravel, and muddy surfaces. The tracks also minimize damage to the ground, making it ideal for use in environmentally sensitive areas. Its mobility allows for quick repositioning on job sites, enhancing work efficiency and productivity.

The diesel engine of this spider crane complies with stringent CE EPA EURO 5 emission standards. This ensures that the crane operates with minimal environmental impact while maintaining high performance and reliability. The use of low-emission diesel fuel reduces harmful emissions, making it suitable for both indoor and outdoor applications. This compliance also ensures that the crane meets the regulatory requirements in various regions, providing peace of mind for users.

One of the standout features of this tracked spider crane is its dual fuel usage capability. It can seamlessly switch between electric and diesel power sources, offering maximum flexibility and cost-effectiveness. In areas with power supply access, the electric mode provides quiet and emission-free operation. In remote locations without power access, the diesel mode ensures continuous operation without interruption. This dual-use feature makes the crane a versatile solution for different working conditions.

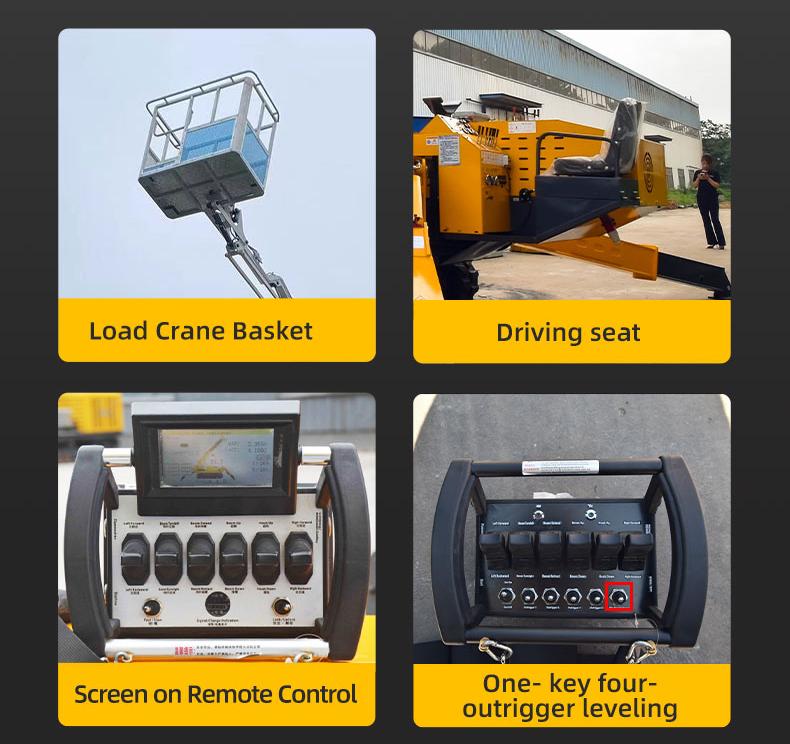

The tracked spider crane is suitable for a wide range of applications, including construction sites, maintenance work, facility management, and event staging. Its compact size and ability to operate in confined spaces make it ideal for tasks such as installing equipment, positioning tools, and performing maintenance in hard-to-reach areas. Its high lifting capacity and precision control also make it suitable for more demanding tasks, such as lifting heavy machinery components or assembling structures.

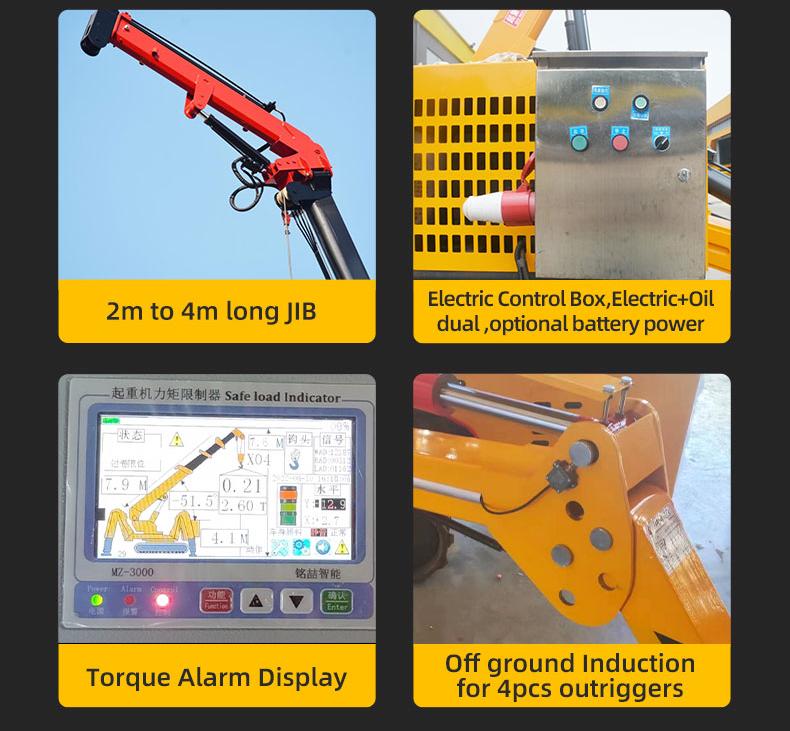

The tracked spider crane is designed with safety and performance in mind. It features advanced hydraulic systems and precise control mechanisms, ensuring smooth and accurate lifting actions. The crane also includes multiple safety systems, such as overload protection, emergency stop systems, and stability sensors, to ensure the safety of operators and the surrounding environment.

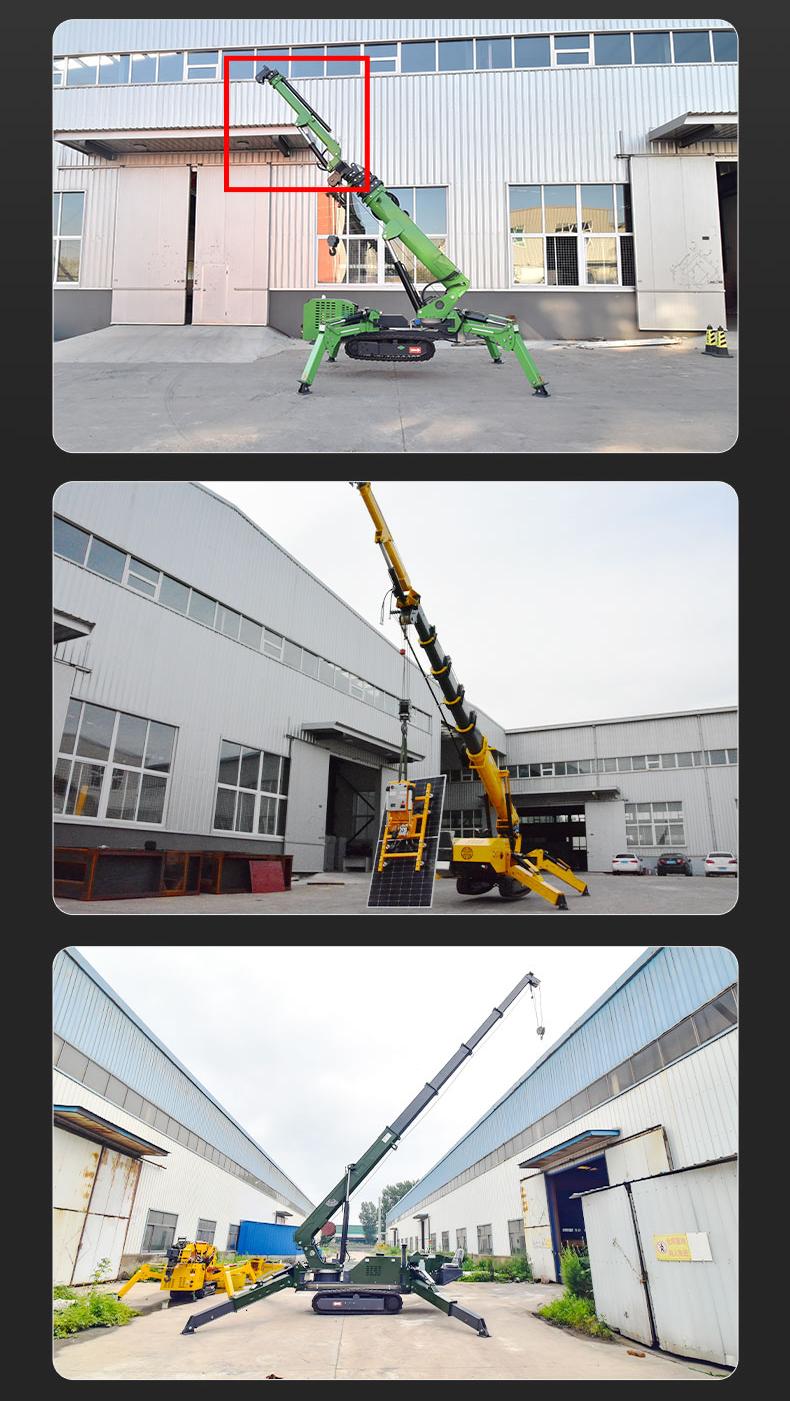

Product Real Photos

The Spider Crane is a versatile construction equipment designed to handle various tasks with ease. With its hydraulic telescopic outriggers, it can stabilize the fuselage effectively, allowing it to adapt to more working conditions. This feature makes the Spider Crane suitable for both uneven terrain and complex construction sites.

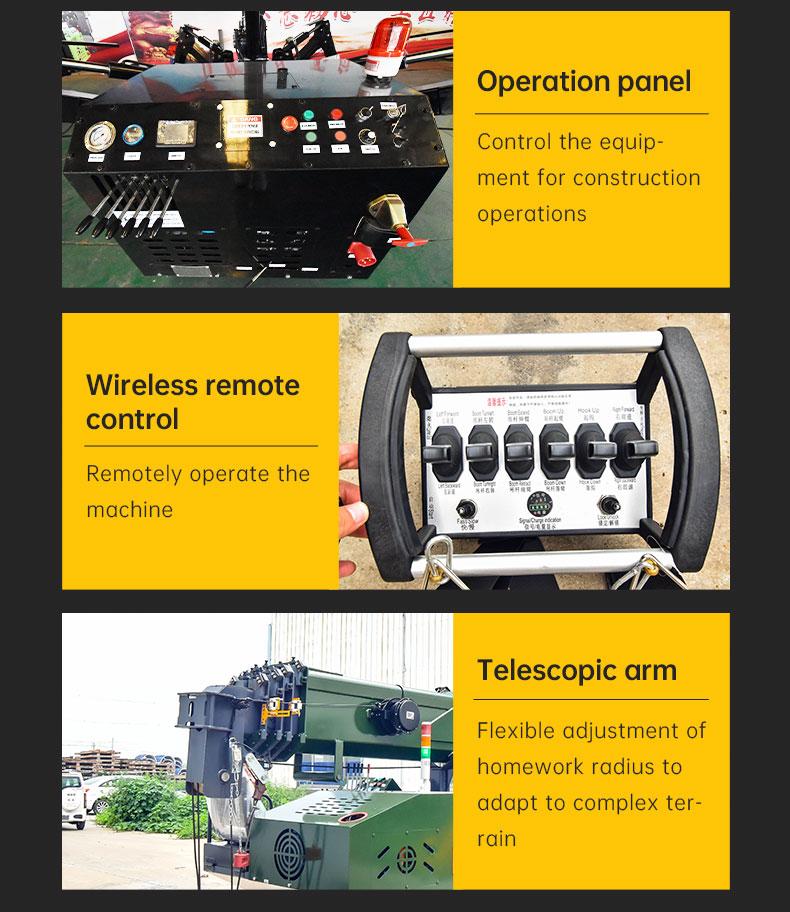

The Crawler Spider Crane is equipped with a crawler chassis, enabling it to travel on muddy roads. This design not only provides excellent mobility but also distributes the weight of the machine evenly, reducing the pressure on the ground and ensuring stability during operations. The operation panel of the Spider Crane is user - friendly, allowing operators to easily control the equipment for various construction operations.

Moreover, the Spider Crane comes with a wireless remote control, which enables operators to remotely control the machine. This feature is particularly useful in situations where direct operation may be difficult or dangerous, enhancing the flexibility and convenience of the Spider Crane.

Another highlight of the Spider Crane is its telescopic arm. The arm allows for flexible adjustment of the working radius, making it easy to adapt to complex terrain. Whether it's for lifting heavy objects in confined spaces or reaching high - altitude work areas, the Spider Crane can handle it with ease. The arm can be extended or retracted according to the requirements of the task, providing maximum flexibility and convenience.

| Model No. | SPCR-1.0 | SPCR-2.0 | SPCR-3.0 | SPCR-5.0 | SPCR-8.0 | SPCR-10 | SPCR-12 | SPCR-14 |

| Specifications | 1T | 2T | 2.95T | 5T | 8T | 10T | 12T | 14T |

| Maximum operating radius | 5.2m*0.25T | 6m*0.25T | 9.3m*0.2T | 14.8m*0.3T | 17.1m*0.3T | 18.6m*0.4T | 21.1m*1.0T | 21.1m*1.2T |

| Maximum above - ground lifting height | 8m | 8m | 9.8m | 16m | 18m | 19.6m | 22m | 22m |

| Maximum below - ground lifting height | 20m | 20m | 45m | 65m | 80m | 80m | 80m | 80m |

| Hoisting method | Hydraulic motor drive | Hydraulic motor drive, high and low speed | ||||||

| Hoist hook lifting speed | ≈2.3m/min | ≈2.3m/min | ≥4.8m/min | 0-11m/min | 0-12m/min | 0-12m/min | 0-12m/min | 0-12m/min |

| Wire rope diameter and length | Φ8mmx20m(Max) | Φ8mmx20m(Max) | Φ8mmx45m(Max) | Φ10mmx70m(Max) | Φ11mmx80m(Max) | Φ11mmx90m(Max) | Φ11mmx100m(Max) | Φ11mmx110m(Max) |

| Jib form | Utype automatic 4section | Utype automatic 5section | Utype automatic 5section | Hexagonal fully automatic 5-segment | Hexagonal fully automatic 5-segment | Hexagonal fully automatic 5-segment | Hexagonal fully automatic 5-segment | Hexagonal fully automatic 5-segment |

| Jib telescopic length / time | 30sec (fully extended) | 30sec (fully extended) | 26sec(fully extended) | 40sec(fully extended) | 50sec(fully extended) | 50sec (fully extended) | 50sec (fully extended) | 50sec (fully extended) |

| Jib angle / time | 0~70°/50sec | 0~70°/50sec | 0~75°/18sec | 0~78°/46sec | 0~78°/60sec | 0~78°/60sec | 0~78°/60sec | 0~78°/60sec |

| Slewing angle / time | 0-360°continuous/ 107sec | 0-360°continuous/45sec | 0-360°continuous/45sec | 0-360°continuous/120sec | 0-360°continuous/120sec | 0-360°continuous/120sec | 0-360°continuous/120sec | 0-360°continuous/120sec |

| Outrigger action form | Manual swing out,automatic leg support | Manual swing out,automatic leg support | Manual swing outn,hydraulic expansion | Manual swing out, hydraulic outriggers | Manual swing out,automatic leg support | Manual swing out,hydraulic expansion | Manual swing out,hydraulic expansion | Manual swing out,hydraulic expansion |

| Travel mode | Hydraulic motor drive | Hydraulic motor drive | Hydraulic motor drive | Hydraulic motor drive, 2-speed | Hydraulic motor drive, 2-speed | Hydraulic motor drive, 2-speed | Hydraulic motor drive, 2-speed | Hydraulic motor drive, 2-speed |

| Travel speed | 0~0.3km/h | 0~0.3km/h | 0~0.8km/h | 0~2km/h | 0~2km/h | 0~2km/h | 0~2km/h | 0~2km/h |

| Gradient climbing ability | 20° | 20° | 20° | 20° | 20° | 20° | 20° | 20° |

| Crawler belt (length*width) | 1110mm*150mm | 1110mm*180mm | 1600mm*230mm | 2200mm*300mm | 2570mm*350mm | 2570mm*400mm | 2570mm*400mm | 3200mm*400mm |

| Overall dimensions (length*width*height) | 2260mm*600mm*1470mn | 2360mm*750mm*1470mn | 3400mm*950mm*1700mm | 4650mm*1400mm*2160mn | 5010mm*1600mm*2200mn | 5550mm*1850mm*2300mn | 6050mm*1850mm*2300mn | 6050mm*2000mm*2300mn |

| Hydraulic oil tank capacity | 20L | 20L | 40L | 70L | 130L | 130L | 130L | 130L |

| Power system | Gasoline engine + three-phase AC asynchronous motor | Diesel engine + three-phase AC asynchronous motor | ||||||

| Gasoline engine: Honda Gx390 | Diesel engine (optional): Changchai EV80+Yanmar 3TNV88+Yunnai YN25GB+Yunnai YN27GBZ+Yuchai | |||||||

| Note: For more parameter configuration information, please contact online customer service | ||||||||

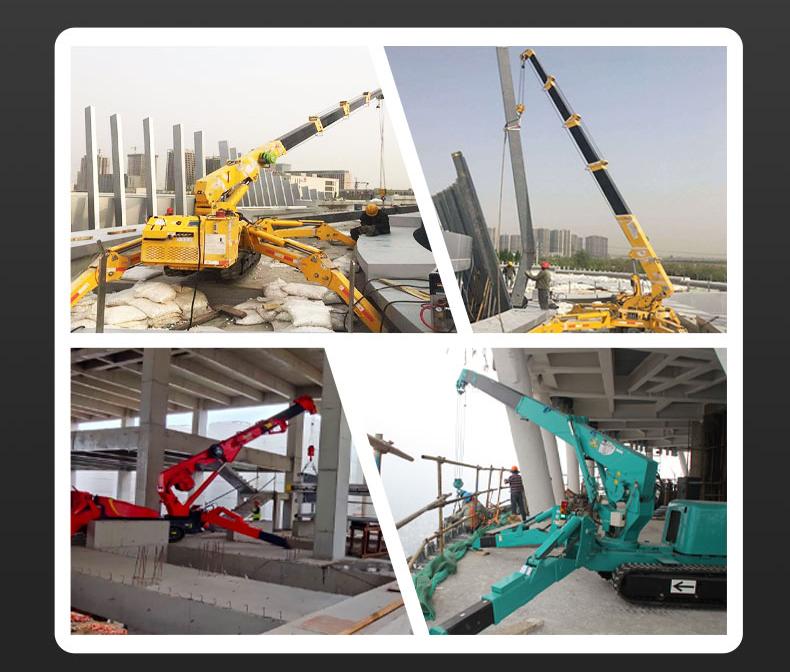

Spider cranes are applicable to a wide range of works including glazing, rooftop, curtain wall installation, operations in restricted/limited access areas, residential and civil construction, works on uneven ground, municipal engineering, stonework as well as other works.

1. Roof work

Spider cranes can be placed on the roof and lift materials from the ground. Achieve shorter construction cycles and cost reductions. Spider cranes can be easily lifted to the roof by tower cranes or elevators.

2. Curtain wall installation

Spider cranes are widely used in curtain wall construction and can be used for vertical transportation, hoisting, etc. They are particularly suitable for the installation of unit panels with large changes in the facade.

3. Glass engineering

By using the vacuum glass suction cups installed on the spider crane search hook, glass can be installed even under the roof.

4. Municipal engineering

Spider cranes have been used in many municipal construction machinery operations due to their flexibility in narrow places. Such as airports, railway stations, large bank construction sites, etc.

5. Power engineering

Spider cranes can perfectly solve the problem that the substation roads and construction sites are narrow, the construction environment is relatively complex, and large cranes cannot enter the construction.

6. Building construction

With its excellent accessibility, spider cranes can be used for installation work in large commercial buildings and construction sites.

Are you a manufacturer or Trader ?

We are a professional manufacture , we have our own R&D team and sales team, we provide one-stop service.

What is your payment term ?

We accept T/T, L/C at sight, Western Union, Paypal etc.

How long is the validity of quotation ?

Generally, our price is valid within 15 days from the date of quotation .The price will be adjusted appropriately according to the price fluctuation of raw material and changes in market .

What is your delivery time ?

Usually, we make merchandise inventory, if we have the products in stock, the delivery time is 5-10 days after receiving the deposit.

If we don't have the products in stock, we will arrange the production right now, the delivery time will be 20-30 days,It depend on the order quantity.

Do you provide OEM/ODM Service ?

Yes, offer us necessary information, we provide custom-make service to meet different needs of global clients with different budgets.

Do you have CE certificate ?

Yes, most of our products have the CE certificate

How can we ensure quality?

The final inspection is always carried out before shipment.

How to install the equipment after purchasing ?

We will provide professional installation video to illustrate.Also provide manual.

Do you offer a guarantee?

Yes, we guarantee our product for one year. Provide after-sales service support and technical support.